A little over a week ago now, on Sunday 29th August 2020, the Victorian Scheduled Demand fell to a level that seemed to be the lowest daytime point during NEM years. Whether it was or not quickly became a moot point, with the ‘all hours’ record minimum point being reset on Sunday 6th September 2020 (8 days later).

However Sunday 29th August was interesting for a number of other reasons, including:

1) What happened to minimum Scheduled Demand levels on a NEM-wide basis (perhaps the lowest on a daytime basis); and

2) The churn in output of Semi-Scheduled assets through the day, contributing to some extreme outcomes for Raw Off-Target, at least in part due to the negative prices in SA, VIC and QLD.

This article next day (part 1 analysis) prompted a question by ‘Kieran’ as follows:

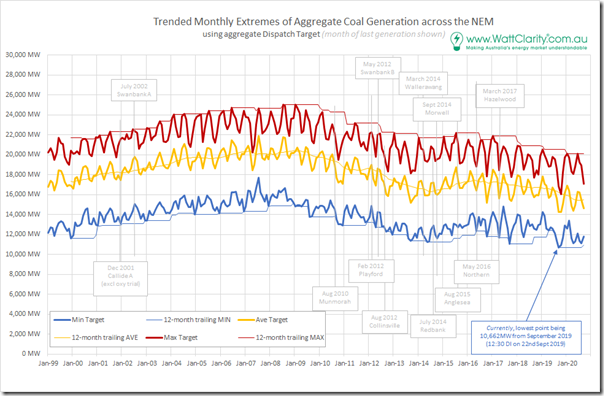

‘Was wondering if this was a minimum record for coal generation (black + brown)? even if not quite since market start, at least minimum for the last 10 years, say?’

Coincidentally, a number of others also asked about the same type of thing.

… and whilst Geoff Eldridge was quick with an answer about a few spot points in time, I was more interested in the trend – so with a short space of time this morning I’ve presented the following trend of monthly stats (minimum, average and maximum) for production from all coal generators – i.e. black and brown together:

Note that in delivering this trend we chose to use aggregate Dispatch Target rather than metered output. There’s merits of each, with the merit of the above being:

1) It shows what the ‘market demand’ was for output from the generator;

2) Aggregate dispatch target won’t show the effect of the reduced supply due to unscheduled trips in units that occur from time to time (i.e. for these dispatch intervals Metered Output < Dispatch Target, although note that a significant portion of the ‘lost’ energy will currently have been made up by other coal units supplying Contingency Raise FCAS services);

3) It also won’t take into account all the additional supply from coal provided for Regulation Raise FCAS services as a result of any collective under-performance* of other units through the normal course of the dispatch process (i.e. for these dispatch intervals, Metered Output > Dispatch Target).

* frequent readers will remember that I’ve been taking a deeper look at extremes in (mostly) collective under-performance, and (less frequently) collective over-performance, of Semi-Scheduled plant as part of broader questions about the scalability and sustainability of the Semi-Scheduled category.

—–

With the all-time peak for NEM-wide demand just above 35,000MW it should be obvious just how significant the fleet of coal units (48 remaining since the closure of Hazelwood in March 2017).

As we explored with GVSC in the Generator Report Card 2018, and will look to update in the next issue, this is both:

1) A reminder of the scale of the challenge that remains to be addressed if we are to meet our Energy Transition objectives; but also

2) A note of caution that a ‘more of the same’ approach (e.g. in terms of the form of support for new entrants) is probably not the most effective way to deliver on the above.

—–

That’s all for now. Might be the shortest analytical article I have ever written?!

An interesting statistic is to look at the capacity factor for the sector. It is one thing to have output reduced by the retirement of a facility (eg Hazelwood) but as players continue to try and compete for an ever decreasing energy “pie” then the financial viability of plants comes into question. The first thing that gets crossed off is reinvestment in reliability and sustaining capital. Nasty little cycle now starts because the plants become less reliable and hence have lower capacity factors and around we go again. The serious issue on the east coast is the lack of mid merit / peaking plants to fill in as coal falls by the wayside and rooftop PV and wind takes the daytime energy. And I’m still looking for the commercial drivers to get investment in same in an energy only market. All is well until a hot and still evening arrives. AEMO are flagging this – it does happen – look at California.

Thanks Andy

This was obviously only a short article. More detailed statistics (>600 pages of them) are compiled for all generators in our ‘Generator Statistical Digest 2019′:

https://wattclarity.com.au/other-resources/detailed-analysis-and-reports/generator-statistical-digest-2019/

… which we will be seeking to update each year from now.

Paul

Thanks Paul for answering my question! I note that last weekend got down to a minimum of 10871 based on the dispatch target metric, so still not quite record breaking but we have a few more spring weekends to go…

To Andy’s point, i understand that in Europe (e.g. UK, Germany) some older coal plants have been configured to run more mid-merit (carbon pricing and lower fuel price differentials made some of them less competitive v CCGTs), i.e. better able to start up, ramp up at a reasonable rate and then ramp down. It seems to be an article of faith that this is not feasible in Australia, but it’s not clear why not – different turbines, possibly? Or is it just economics – there would be fewer hours in a typical year in which to earn one’s money back?

Kieran, Coal plant response will never get close to an OCGT. Once synchronised and part loaded they can get close to an CCGT in terms of loading rates (they will usually be also limited by their steam cycle). You are right, much can (and is being) done mainly around I & C to improve start up and shut down times, however at the end of the day big, thick walled steel components have limits of heating and cooling rates and hence consumption of fatigue life. Given many are already older plants with somewhat imperfect history of life already consumed (remember,many did not have control systems that modelled life consumption in the 1980’s and before when they were built) so it can be a bit of a raffle. New I & C lets advanced materials modelling be put in to manage life consumption. It gets very expensive when you find a big crack in something at a subsequent overhaul (that you might have to schedule just so you can look – this in itself is expensive). As I say a viscous little circle and it is all economics if the plant cannot earn the revenue to wash its face in an energy only market. Capacity markets can help but the market purists hate these. Not withstanding Govt policy on carbon, I don’t think there are any of the original 4 x 500MW stations left in the UK now. Simply couldn’t get a run. Even Drax (6 x 600MW) survives only as an imported biomass burner. Now there are CCGT plants having trouble because of increasing gas prices.

My [rejected] comment was obviously an unacceptable comment on the ‘slow decline of coal’….no doubt the foreign-made juggernaut and those making their fortunes out of it just can’t cope with the milch cow consumers supposedly driving the ‘transition’…being permitted to have any chance to have their perspective on it published.

Good for you Paul McCardle…bad for Australia.

Er, ‘metro70’, I appreciate your perspective – however let’s not try to ascribe motivation via conspiracy theory (e.g. ‘just can’t cope with…’) when the facts are simpler.

There is an automated spam filter used on this site to make the site usable, and it appears to have deemed your comment (a long line of text with many capitalised words and other elements that increase the risk it is spam) as such.